OUR PROCESS

From Fish to Finished Product

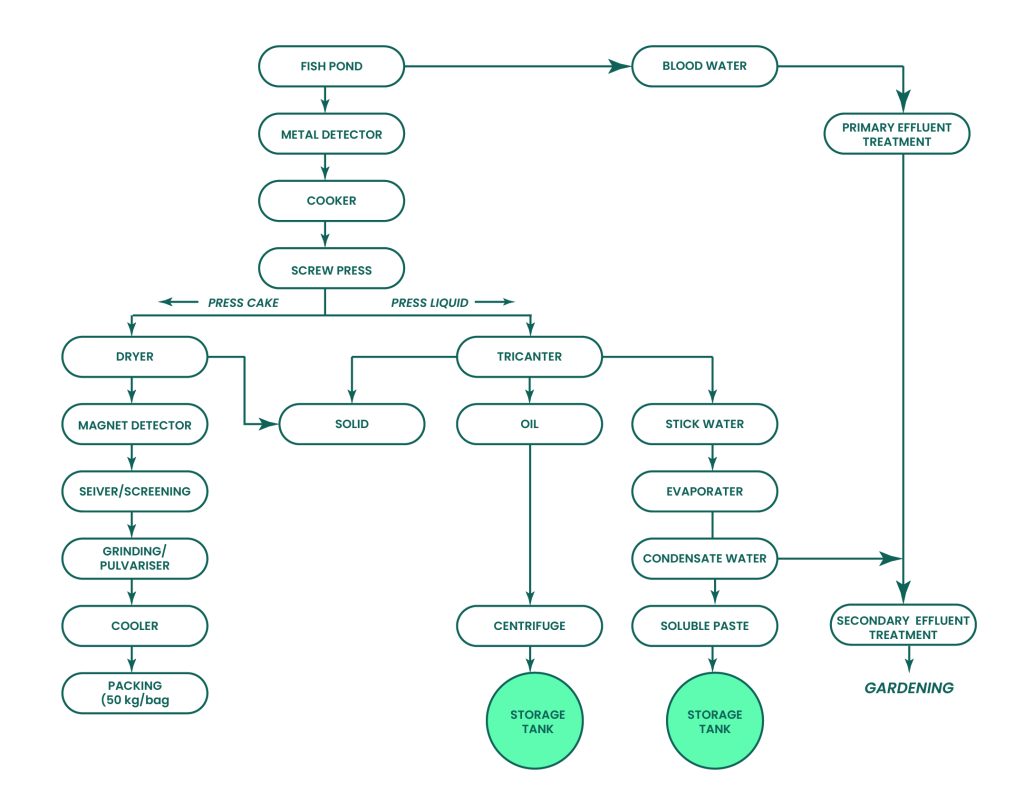

At Freelance Fishmeal, our production process is designed for efficiency and quality. It begins with the careful selection of fish, which are then processed through a series of steps including cooking and pressing. The press separates the fish into a solid ‘press cake’ and a liquid. The press cake is then dried, ground, and screened to produce high-quality fishmeal, which is then cooled and packed in 50 kg bags. Concurrently, the liquid is processed to extract valuable fish oil and a soluble paste. The remaining water is treated in our advanced effluent treatment plant, ensuring environmentally responsible disposal. This comprehensive approach allows us to produce superior fishmeal while minimizing waste.

Highlights of Our Fishmeal Production Process

-

Initial Processing:

The process starts with fresh fish, which are first passed through a metal detector before being cooked and pressed to separate the solids from the liquid.

-

Solid (Press Cake) Processing:

The solid press cake is dried, screened, and then ground into fine fishmeal powder. This powder is then cooled and packed into 50 kg bags for delivery.

-

Liquid By-product Extraction:

The liquid separated during pressing is processed to extract valuable fish oil and a soluble paste, which are both stored in tanks.

-

Water Treatment:

All wastewater from the production is channeled to our effluent treatment plant, ensuring all discharge is managed in an environmentally responsible manner.